Description

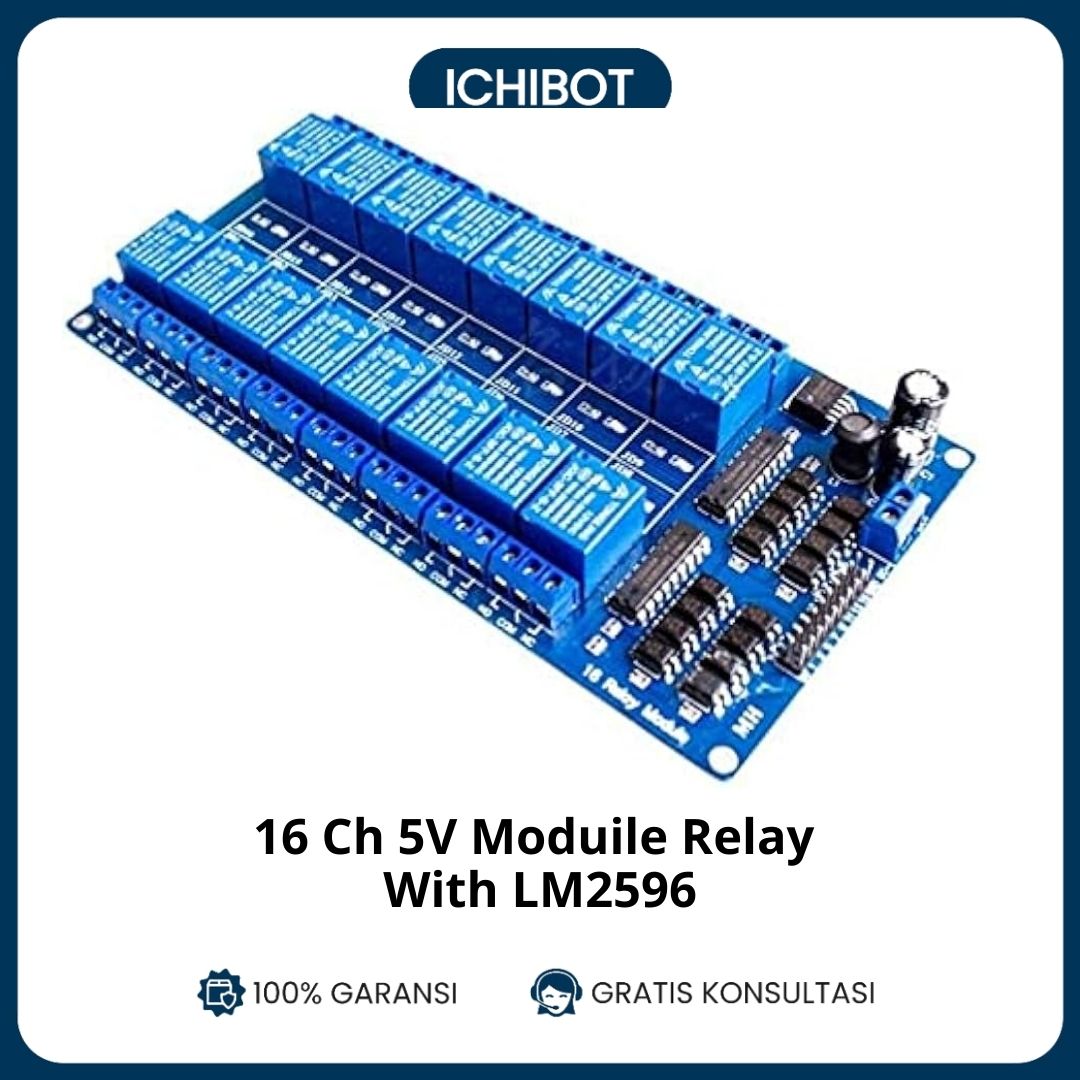

This is a 5V 16 Channel Active Low Relay Module with Light Coupling LM2576 Power Supply that can control various appliances and other high-current equipment. Microcontrollers can directly control it. Each individual relay requires 15-20mA of driver current. The board includes an LED that indicates the status of the relay output and a standard interface that can be controlled directly by many popular microcontrollers such as Arduino.

Package Includes:

- 1 x 5V 16 Channel Relay Module Low Trigger with Optocouplers and LM2576buck converter

Features:

- 5V relay with AC contact capacity of 10A 250V and optocoupler protection.

- The onboard power supply module does not need an external power supply. I / O port driver is active and low.

- The module can be used as a microcontroller development board module and also as appliance control, PLC extended output.

- It is using the industry’s top-quality isolation optocouplers, strong anti-jamming ability, and stable performance.

- The 1-16 road can be any full on/off or any road.

- All interfaces can be directly connected through the terminal leads, very convenient.

Description:

This is a 5V 16 Channel Relay Module with an LM2576 Light Coupling Power Supply that can control a variety of appliances and other high-current equipment. It is directly controllable by microcontrollers. Each relay necessitates 15-20mA of driver current. The board features an LED that indicates the status of the relay output as well as a standard interface that can be directly controlled by many popular microcontrollers such as Arduino. The 5V electromechanical relay module with a 250V AC contact capacity also includes light coupling protection (optocoupler) for control circuitry isolation. An external power supply is not required for the plate load power module. It is compatible with all SCM drives.

The LM2596S buck chip in this relay module has a slightly high temperature, which is a normal phenomenon for relays with long working hours. 4 relay load power to leave some margin, should avoid high-power (about 2000W) and long working environments, as this will have an impact on the product’s life.

Principle of Work:

An iron core is surrounded by a control coil. As shown, the power source is given to the electromagnet through a control switch and through contacts to the load. When current starts flowing through the control coil, the electromagnet starts energizing and thus intensifies the magnetic field. Thus the upper contact arm starts to be attracted to the lower fixed arm and thus closes the contacts causing a short circuit for the power to the load. On the other hand, if the relay was already de-energized when the contacts were closed, then the contact move oppositely and make an open circuit.

As soon as the coil current is off, the movable armature will be returned by a force back to its initial position. This force will be almost equal to half the strength of the magnetic force. This force is mainly provided by two factors. They are spring and also gravity. Relays are mainly made for two basic operations. One is low voltage application and the other is high voltage. For low-voltage applications. and low-level triggered functionality will allow the current to go through the power line when the control signal is GND or close. optocoupler on the other hand makes real photo isolation between the relay and the MCU which is very good to minimize the distortion from the other side

Pinout of the Module:

-

VCC DC +: Connected to 12v

-

DC -: Connected to GND